Armouring

Armoring is an art at ARTAN

SERVING GLOBALLY

ARMOURING CAN BE CLASSIFIED INTO LEVEL 4, LEVEL 5, LEVEL 6 & LEVEL 7

Stage 1

An order document is initiated according to the specifications and requirements of the client. Detailed scrutiny regarding the levels of protection and the corresponding safety apparatus which include materials, structuring, etc will be done at this stage. Thus armoring process is formally initiated at this stage

Stage 2

The vehicle’s interior is completely dismantled exposing only its frame. All the interior parts of the vehicle are categorically separated and a number is assigned to each part so that any misplacing can be ruled out.

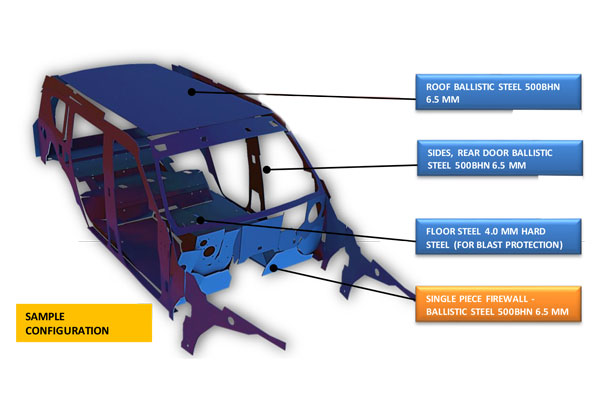

The armoring process is continued by measuring the floor, ceiling, doors, and firewall, which enables us to cut and construct the pieces of ballistic material necessary to cover each of these areas. These materials stop any kind of metal fragments from penetrating the passenger compartment.

Stage 3

At this stage, we revamp the fuel tank with ballistic nylon and cover it with a coating that is water-resistant and can endure hostile climate. Artan's technicians then scrutinize the suspension and braking systems of the vehicle and modify them to support the added payload due to the armoring process.

Stage 4

The batteries are covered using high-grade materials. The fuse box and ECM are covered with protective ballistic steel.

Stage 5

Here, according to the preference of the customer, we install bullet-proof glass windows. These are specially crafted to fit OEM window channels, providing them great factory finish.

Stage 6

High-performance guaranteed run-flat-tire inserts are mounted to the vehicle. At this stage, additional options according to the needs of various customers that include defense apparatus; tactical systems, etc are fitted onto the vehicle.

Final stage

At Artan we modify the interior of the vehicle to raise its safety features. We emphasize giving the best luxury and beauty to the vehicle while detailing every aspect. Now the vehicle is fully armored to provide you the best of the experience. After settling the customer accounts, your vehicle is all set for final delivery.

Ballistic Specifications

Harrow Security Vehicles in B6 level are armoured using materials, both opaque and

transparent, that meet or exceed the requirements of the European CEN 1522/23 and CEN

1063 standards to the level FB6 for opaque areas and BR6 for transparent areas.

Armouring

All four sides of the passenger compartment and the roof of the vehicle are protected using high-quality armour steel and glass defeating 7.62x51mm M80 Nato Ball ammunition (U.S. NIJ level III, CEN level FB6/BR6) and 5.56x45 SS109 ammunition (CEN level FB5/BR5 and FB6/BR6) at 0° incidence (90° to the surface) and 10m range according to CEN1063 and CEN1522.

Opaque Areas:

All opaque areas including the roof are protected against the following and all lesser weapons/ ammunitions at 90° impact angle in accordance with the above specifications.

- Calibre 7.62 x 39 mm, FJ/PB/FeC, AK 47 Kalashnikov

- Calibre 5.56 x 45 mm, FJ/PB/SCP, M16 Colt

- Calibre 7.62 x 51 mm, FJ/PB/SC, (FN) “FAL” / “LAR” NATO rifle

Transparent Areas:

All transparent areas are multi-layer and polycarbonate coated to protect against the following and all lesser weapons/ ammunitions at 90° impact angle in accordance with the above specifications.

- Calibre 7.62 x 39 mm, FJ/PB/FeC, AK 47 Kalashnikov

- Calibre 5.56 x 45 mm, FJ/PB/SCP, M16 Colt

- Calibre 7.62 x 51 mm, FJ/PB/SC, (FN) “FAL” / “LAR” NATO rifle

Floor

The floor of the vehicle is designed to defeat the

following hand grenades

- Two DM 51 (German Norm) detonated simultaneously In addition, the floor also offers protection against anti-personnel mines.

Armouring design:

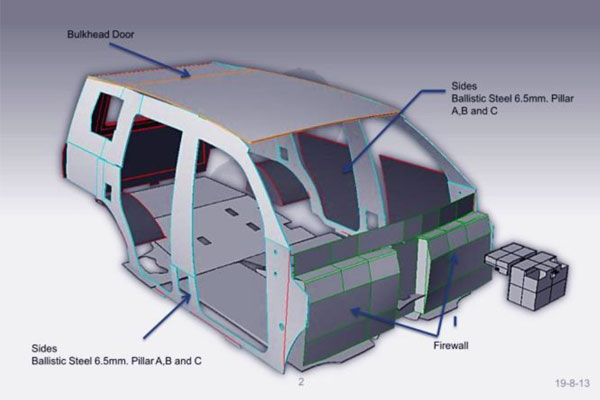

- The armouring is integrated inside the vehicle’s cab and forms a complete selfsupporting structure so as to avoid excessive stress on the vehicle’s original structure.

- The interior armour frame provides overlap for the large-surface armour components such as the door armour-plates and the windows.

- Hinge mounting points are reinforced both in the pillars and in the doors in a way that the armouring of the door is supported by the armouring of the pillar.

- Heavy-duty hinges with in-built door-stop.

- Fuel-tank(s) protected with steel armourplates.

- The battery and control module of the engine are protected to the same level as the opaque areas.